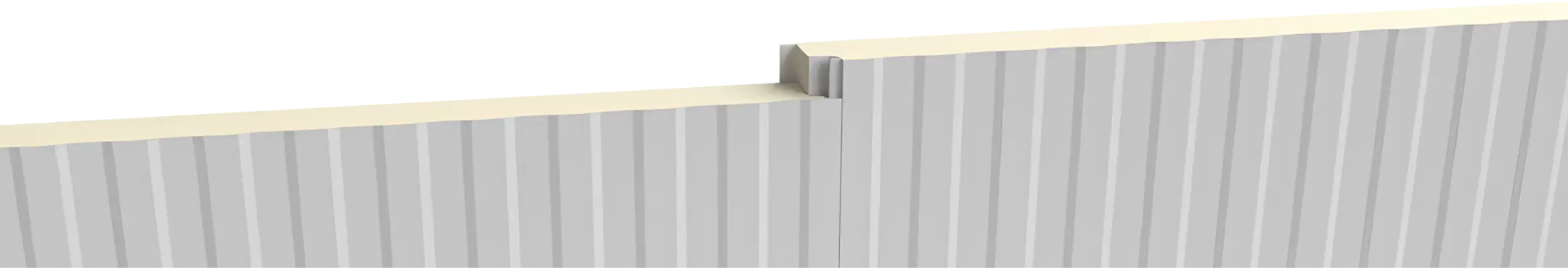

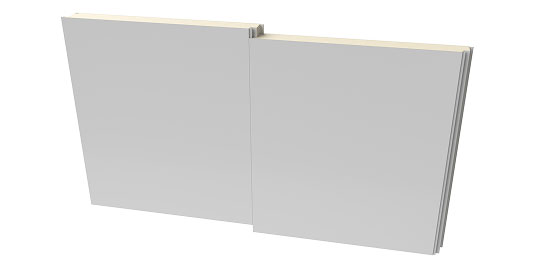

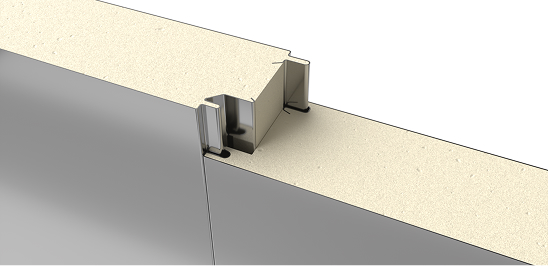

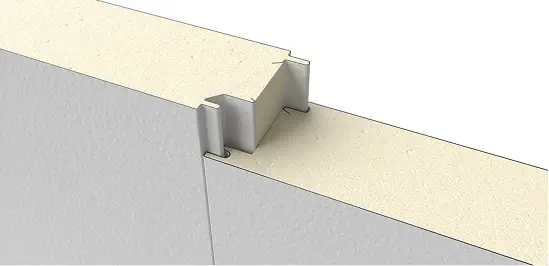

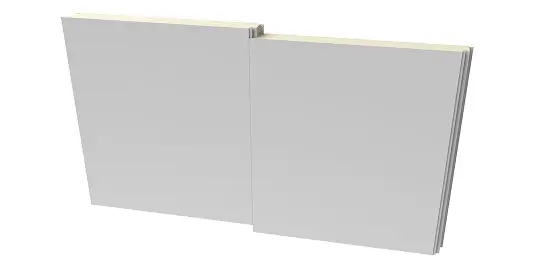

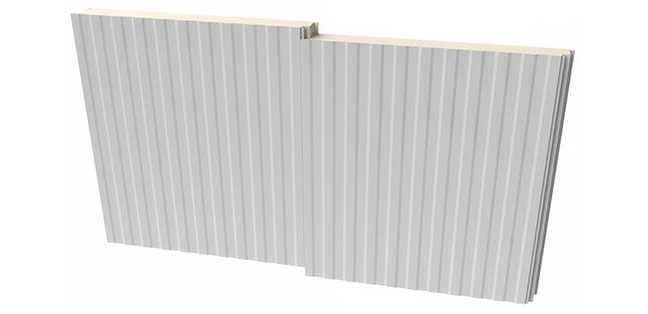

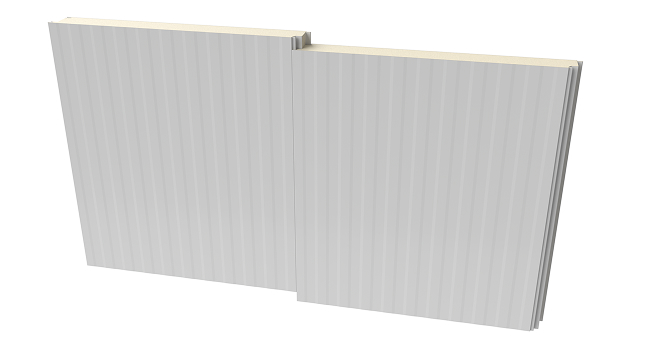

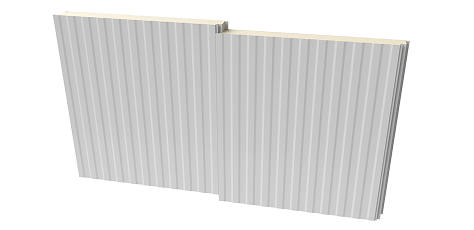

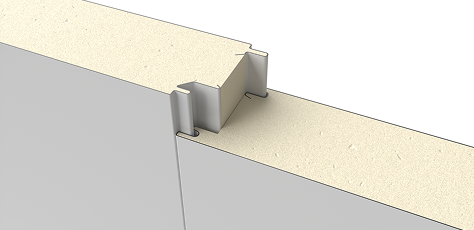

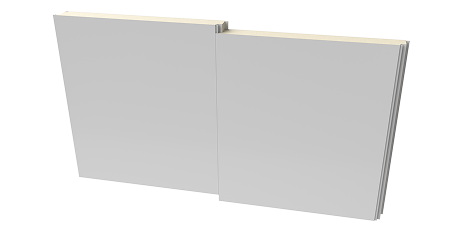

PermaCore Hidden Fastener No Profile panels offer a clean, uninterrupted surface that complements demanding environments while delivering reliable performance. With built-in insulation for energy efficiency, a no-profile finish for a smooth modern look, and a concealed fastening system that ensures precise installation, these panels are designed for excellence in cold storage, food processing, and controlled-environment construction.

At PermaTherm, we believe a panel is only as strong as the support behind it. That is why our team works alongside you from the first design conversation through the final installation, providing practical expertise and solutions tailored to your project. Choosing PermaTherm means more than choosing a product. It means choosing a partner committed to your success.

PermaTherm’s PermaCore product line provides the maximum R-value per inch. Utilizing Poly-Iso Technology (Foamed in Place), PermaCore panels meet the highest standards. With PermaCore, we currently provide the following panel-joint options:

*Only PermaCore delivers factory direct notched freezer panels. The ultimate way to prevent thermal bridging and save you countless hours of field cutting!

PermaCore panels can be used across any application from food processing, to growing environments, clean rooms, and cold storage. PermaTherm’s PermaCore panel is the standard for insulated wall panels.

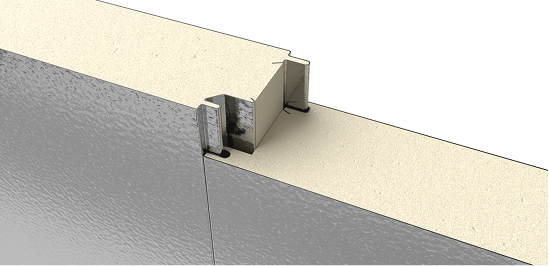

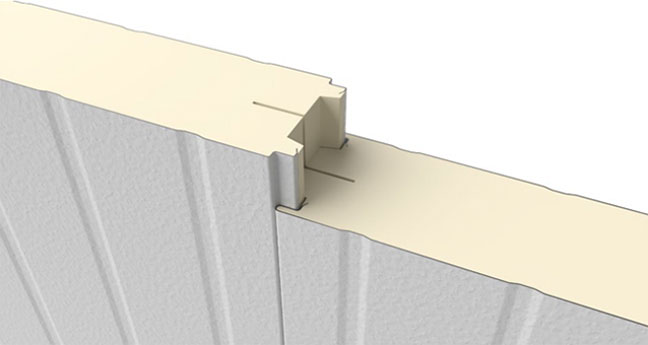

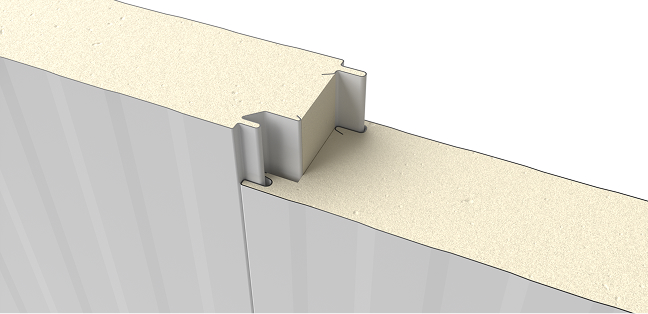

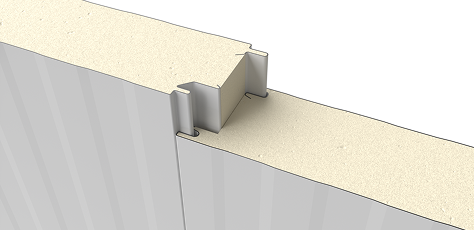

PermaCore PHF43 features the classic Hidden Fastener joint and is suitable for various applications including building exteriors, partition/divider walls, ceilings, and box-in-a-box applications.

| Product: PermaCore-PHF43 Data Sheet | |

|---|---|

| Panel Use: | Exteriors, Partition Walls, Ceilings, Box-in-a-box |

| Profiles: | Light Mesa, Heavy Mesa, Shadowline, No Profile |

| Coverage Width: | 43" |

| Available Thickness: | 2”, 2.5”, 3”, 4”, 5”, 6”, 8” |

| Length: | 8’-0” to 50’-0”* |

| Metal Gauge: | 26, 24, 22 |

| Metal Type: | Galvanized, Stainless Steel or Galvalume |

| Texture: | Embossed, Heavy Embossed, or Smooth |

| Paint Type: | Siliconized Polyester, Fluropon PVDF |

| Core: | Polyisocyanurate (Foamed in Place) Insulation |

| R-Value: | R-8.2 Per Inch of Thickness |

*For 2” Max is 40’ and 2.5” Max is 45’

All PermaTherm products are warranted to be free from defects in materials and workmanship for a period of two years from the date of shipment.

A certain amount of “waviness,” or “oil canning,” is inherent in any product made from sheet metal. Installation of large areas of metal panels, or installation of panels to misaligned structures, will cause unnatural stresses, increasing the likelihood of oil canning.

A stucco-like embossed texture in a pre-coated material will reduce the visual effect of oil canning. Oil canning does not affect the structural or thermal integrity of the panel. Minor waviness of the panel does not indicate a defective panel, and is not cause for product refusal.

Minor blisters can sometimes occur when the panel’s exterior face is exposed to the sun. This is caused by the thermal expansion of a blowing agent, which is trapped under the panel face. This is a common phenomenon and is easily repaired, and is not cause for product refusal.

Finished panels free of surface imperfections (dents, mars, scratches, etc.) visible with panel in position of intended use and view under good light from intended installed distance or 8 ft., whichever is greater.

Permacore: Insulated metal wall and ceiling panels

Profiles: Light Mesa, Standard Mesa, Classic Shadow Line, Sleek

Width: 43” & 45.5” Max

Gauge: 26-gauge min. (facer and liner)

Texture Finish: Embossed or Smooth

| Panel Thickness (In.) | 2″ | 2.5″ | 3″ | 4″ | 5″ | 6″ | 8″ |

|---|---|---|---|---|---|---|---|

| R-Value at 35⁰ | 16.26 | 20.33 | 24.40 | 32.52 | 40.65 | 48.78 | 65.04 |

| R-Value at 75⁰ | 15.08 | 18.85 | 22.62 | 30.16 | 37.70 | 45.24 | 60.32 |

R-Values ascertained via ASTM C518 testing.

(Approx 1/16th Depth)

(Approx 1/8th Depth)

(Classic Shadow Line)

For contractors and project teams working with PermaTherm’s insulated metal panels, this comprehensive guide covers everything you need to ensure a successful installation—from material handling and storage to sealant application and detailed connection drawings. Backed by over 30 years of cold storage panel expertise, this document is essential reading before any panels are ordered or installed.

DOWNLOAD PDF| 26 Gauge 26 Gauge | 26 Gauge 22 Gauge | 24 Gauge 22 Gauge | |||

|---|---|---|---|---|---|

| Wall and Ceiling panels | Wall and Ceiling panels | Wall and Ceiling panels | |||

| Inches | Square Feet | Inches | Square Feet | Inches | Square Feet |

| 2 | 2.23 | 2 | 2.74 | 2 | 2.95 |

| 2.5 | 2.32 | 2.5 | 2.85 | 2.5 | 3.08 |

| 3 | 2.40 | 3 | 2.83 | 3 | 3.15 |

| 4 | 2.63 | 4 | 3.15 | 4 | 3.36 |

| 5 | 2.83 | 5 | 3.36 | 5 | 3.55 |

| 6 | 2.97 | 6 | 3.50 | 6 | 3.72 |

| 8 | 3.32 | 8 | 3.85 | 8 | 4.05 |

| 26 Gauge 24 Gauge | 24 Gauge 24 Gauge | 22 Gauge 22 Gauge | |||

|---|---|---|---|---|---|

| Wall and Ceiling panels | Wall and Ceiling panels | Wall and Ceiling panels | |||

| Inches | Square Feet | Inches | Square Feet | Inches | Square Feet |

| 2 | 2.45 | 2 | 2.66 | 2 | 3.25 |

| 2.5 | 2.55 | 2.5 | 2.80 | 2.5 | 3.36 |

| 3 | 2.65 | 3 | 2.85 | 3 | 3.45 |

| 4 | 2.85 | 4 | 3.03 | 4 | 3.66 |

| 5 | 3.06 | 5 | 3.27 | 5 | 3.85 |

| 6 | 3.22 | 6 | 3.46 | 6 | 4.00 |

| 8 | 3.57 | 8 | 3.75 | 8 | 4.35 |

PermaTherm’s PHF43 span and load data is provided for common applications utilizing insulated metal panels and is provided in the following tables.

For questions about your application, don’t hesitate to contact Permatherm and the project management team for assistance.

Allowable Single Span for Inward or Outward Distributed Load (5 psf)

| Panel Thickness | Design Criteria | Allowable Span | ||

|---|---|---|---|---|

| Bending Stress | Shear Stress | Deflection Limit | ||

| 2″ | 25′-26″ | 50′-0″* | 21′-0″ | 21′-0″ |

| 2.5″ | 28′- 7″ | 50′- 0″* | 24′- 8″ | 24′- 8″ |

| 3″ | 31′- 4″ | 50′- 0″* | 28′- 1″ | 28′ 1″ |

| 4″ | 36′- 4″ | 50′- 0″* | 34′-5″ | 34′- 5″ |

| 5″ | 42′- 7″ | 50′- 0″* | 40′- 0″ | 40′- 0″ |

| 6″ | 48′- 9″ | 50′- 0″* | 45′- 4″ | 45′- 4″ |

| 8″ | 50′- 0″* | 50′- 0″* | 50′- 0″* | 50′- 0″* |

Notes:

Allowable Single Span for Inward or Outward Distributed Load (5 psf)

Panel Strength, Deflection Limit Criteria (L/120), and Temperature Differential

| Panel Thickness | Temperature Differential | |||

|---|---|---|---|---|

| 𝝙=0°F | 𝝙=35°F | 𝝙=70°F | 𝝙=105°F | |

| 2″ | 21′- 0″ | 17′- 8″ | 14′- 7″ | 12′- 1″ |

| 2.5″ | 24′- 8″ | 21′- 1″ | 17′- 8″ | 14′- 9″ |

| 3″ | 28′- 1″ | 24′- 3″ | 20′- 7″ | 17′-5″ |

| 4″ | 34′-5″ | 30′-2″ | 26′- 1″ | 22′-5″ |

| 5″ | 40′- 0″ | 35′-5″ | 31′- 0″ | 26′- 11″ |

| 6″ | 45′- 4″ | 40′-5″ | 35′- 8″ | 31′- 3″ |

| 8″ | 50′- 0″* | 49′-6″ | 44′- 3″ | 39′- 4″ |

Notes:

Allowable Single Span for Inward or Outward Distributed Load (5-35 psf)

Panel Strength & Deflection Limit Criteria (L/240)

| Panel Thickness | Distributed Load | ||||||

|---|---|---|---|---|---|---|---|

| 5 psf | 10 psf | 15 psf | 20 psf | 25 psf | 30 psf | 35 psf | |

| 2″ | 16′ 1″ | 12′- 1″ | 10′- 0″ | 8′-8″ | 7′- 9″ | 7′- 0″ | 6′- 4″ |

| 2.5″ | 19′- 0″ | 14′-5″ | 12′- 1″ | 10′- 7″ | 9′-6″ | 8′- 8″ | 7′- 11″ |

| 3″ | 21′- 9″ | 16′- 7″ | 14′- 0″ | 12′- 4″ | 11′- 2″ | 10′- 3″ | 9′-5″ |

| 4″ | 26′- 10″ | 20′-8″ | 17′- 8″ | 15′-8″ | 14′- 3″ | 13′- 2″ | 12′- 3″ |

| 5″ | 31′- 3″ | 24′- 2″ | 20′- 7″ | 18′- 4″ | 16′- 8″ | 15′-5″ | 14′-5″ |

| 6″ | 35′-5″ | 27′- 4″ | 23′-5″ | 20′- 10″ | 19′- 0″ | 17′- 7″ | 16′ 5″ |

| 8″ | 42′- 11″ | 33′- 3″ | 28′-5″ | 25′- 4″ | 23′- 1″ | 21′- 4″ | 19′- 11″ |

Notes:

| TYPE | PROTOCOL | DESCRIPTION | RESULTS |

|---|---|---|---|

| ENVIRONMENTAL PERFORMANCE | ASTM C518 | Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus | K-Factor 0.138 BTU-in/hr-ft2-F0 at 75° mean K-Factor 0.130 BTU-in/hr-ft2-F0 at 35° mean |

| ASTM E283 | Rate of Air Leakage Through Exterior Windows, Curtain Walls and Doors Under Specified Pressure Differences Across the Specimen | 0.0011-cfm/sf at 20-psf | |

| ASTM E331 | Water Penetration of Exterior Windows, Skylights, Doors and Curtain Walls by Uniform Static Air Pressure Difference | Zero penetration at 20-psf | |

| FOAM CORE CHARACTERISTICS | ASTM C273 | Shear Properties of Sandwich Core Materials | Shear Strength = 16-psf |

| ASTM D1621 | Compressive Properties of Rigid Cellular Plastics | Compressive Strength – 18-psf | |

| ASTM D1622 | Apparent Density of Rigid Cellular Plastics | Apparent Density – 2.50-pcf Nominal | |

| ASTM Dl623 | Tensile and Tensile Adhesion Properties of Rigid Cellular Plastics | Tensile Strength – 21-psf | |

| FIRE RESISTANCE | ASTM E84 | Surface Burning Characteristics of Building Materials | Flame Spread < 10, Smoke Developed < 85 |

| NFPA 285 | Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Non-Load-Bearing Wall Assemblies Containing Combustible Components | Passed – see Intertek listing Intertek.com | |

| FM 4880 | Factory Mutual Approval Standard for Class l Fire Rating of Insulated Wall or Wall and Roof/Ceiling Panels, Interior Finish Materials or Coatings and Exterior Wall Systems | Passed (Factory Mutual website) | |

| NFPA 286 | Standard Fire test for internal walls and ceiling | Passed | |

| IMPACT RESISTANCE | TAS 201 | Florida Building Code Impact Test Procedure | Passed |

| ENGINEERING PROPERTIES | FM 4881 | Factory Mutual Approval Standard for Class l Exterior Wall Systems | Passed See Load Charts ( Factor Mutual website) |

| ASTM E1592 | Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference | See Load Tables | |

| ASTM E72 | Strength Tests of Panels for Building Construction | See Load Tables | |

| APPROVALS | FM 4882 | Factory Mutual approval for Clean Rooms | Approved |

| State of Florida | Florida Product Approval | Approved # FL47552 | |

| IAS | International Association of Steel Buildings | Accredited AC-473 |

SECTION 07435

INSULATED METAL WALL PANELS

General: Construct panel system to provide for expansion and contraction of component materials without causing buckling, failure of joint seals, undue stress on fasteners, other detrimental effects to the panel system or adjacent building systems, or warping of faces of panel system.

Category: Structural Components. Subcategory: Structural Wall.

agents, resulting in zero ODP and zero VOC production.

The perfect compliment to the perfect panel, powered by PRISM. Leveraging 35+ years of expertise, PRISM automatically calculates the details, trim and accessories necessary for your project, down to the last screw.

The PermaTherm Guaranteed Take Off (GTO) means we get it right the first time and cover any inaccuracies. We do not outsource, we design and produce every trim ourselves, ensuring a perfect fit and consistent quality for every project. From flat batten to base channel to inside angle, you can source your trim and accessories directly from PermaTherm. We prioritize by shipping trim before we ship panels, so you can install on your schedule.

Click on the button below to explore how PermaTherm’s >150 trim and accessory products are incorporated into our details.

EXPLORE THE PHF DETAIL DRAWINGSHidden Fastener Panels are primary used in the followed key applications:

PermaTherm panels ensure climate control and durability for distribution centers, freight hubs, and 3PL logistics facilities.

More About this Industry

PermaTherm panels are GMP-compliant and support clean, controlled environments in pharmaceutical and life science facilities.

More About this Industry

PermaTherm panels support grow rooms and greenhouses with excellent insulation and humidity control.

More About this Industry

PermaTherm panels provide dust-free, dehumidified insulation solutions for clean rooms, battery plants, and sensitive manufacturing.

More About this Industry